Product Description

R902137627 A2FE125/61W-VAL100 Features:

R902137627 A2FE125/61W-VAL100 Technical data:

| Size | 28 | 32 | 45 | 56 | 63 | 80 | 90 | 107 | 125 | 160 | 180 | 250 | 355 | |||

| Displacement | Vg | cm³ | 28.1 | 32 | 45.6 | 56.1 | 63 | 80.4 | 90 | 106.7 | 125 | 160.4 | 180 | 250 | 355 | |

| Nominal pressure | pnom | bar | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 350 | 350 | |

| Maximum pressure | pmax | bar | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 400 | 400 | |

| Maximum speed | nnom 1) | rpm | 6300 | 6300 | 5600 | 5000 | 5000 | 4500 | 4500 | 4000 | 4000 | 3600 | 3600 | 2700 | 2240 | |

| nmax 2) | rpm | 6900 | 6900 | 6200 | 5500 | 5500 | 5000 | 5000 | 4400 | 4400 | 4000 | 4000 | ||||

| Inlet flow 3) | at nnom | qV | l/min | 177 | 202 | 255 | 281 | 315 | 362 | 405 | 427 | 500 | 577 | 648 | 675 | 795 |

| Torque 4) | at pnom | M | Nm | 179 | 204 | 290 | 357 | 401 | 512 | 573 | 679 | 796 | 1021 | 1146 | 1393 | 1978 |

| Rotary stiffness | c | kNm/rad | 2.93 | 3.12 | 4.18 | 5.94 | 6.25 | 8.73 | 9.14 | 11.2 | 11.9 | 17.4 | 18.2 | 73.1 | 96.1 | |

| Moment of inertia for rotary group | JTW | kg·m² | 0.0012 | 0.0012 | 0.0024 | 0.0042 | 0.0042 | 0.0072 | 0.0072 | 0.0116 | 0.0116 | 0.022 | 0.022 | 0.061 | 0.102 | |

| Maximum angular acceleration | ɑ | rad/s² | 6500 | 6500 | 14600 | 7500 | 7500 | 6000 | 6000 | 4500 | 4500 | 3500 | 3500 | 10000 | 8300 | |

| Case volume | V | l | 0.2 | 0.2 | 0.33 | 0.45 | 0.45 | 0.55 | 0.55 | 0.8 | 0.8 | 1.1 | 1.1 | 2.5 | 3.5 | |

| Weight (approx.) | m | kg | 10.5 | 10.5 | 15 | 18 | 19 | 23 | 25 | 34 | 36 | 47 | 48 | 82 | 110 | |

| 1) | These values are valid at: - for the optimum viscosity range from vopt = 36 to 16 mm2/s - with hydraulic fluid based on mineral oils |

| 2) | Intermittent maximum speed: overspeed for unload and overhauling processest, t |

| 3) | Restriction of input flow with counterbalance valve |

| 4) | Torque without radial force, with radial force see table "Permissible radial and axial forces of the drive shafts" |

Note

Speed range

No limit to minimum speed nmin. If uniformity of motion is required, speed nmin must not be less than 50 rpm.

| Determining the operating characteristics | ||

| Inlet flow |

| [l/min] |

| Rotational speed |

| [rpm] |

| Torque |

| [Nm] |

| Power |

| [kW] |

| Key | |

| Vg | Displacement per revolution [cm3] |

| Δp | Differential pressure [bar] |

| n | Rotational speed [rpm] |

| ηv | Volumetric efficiency |

| ηhm | Hydraulic-mechanical efficiency |

| ηt | Total efficiency (ηt = ηv • ηhm) |

|

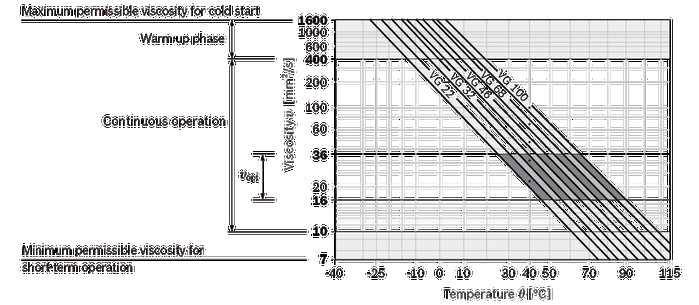

| Viscosity | Shaft | Temperature1) | Comment |

| Cold start | νmax ≤ 1600 mm²/s | NBR2) | ϑSt ≥ -40 °C | t ≤ 3 min, without load (p ≤ 50 bar), n ≤ 1000 rpm, |

| FKM | ϑSt ≥ -25 °C | |||

| Warm-up phase | ν = 400 … 1600 mm²/s |

| t ≤ 15 min, p ≤ 0.7 • pnom and n ≤ 0.5 • nnom | |

| Continuous operation | ν = 10 … 400 mm²/s3) | NBR2) | ϑ ≤ +78 °C | measured at port T |

| FKM | ϑ ≤ +103 °C | |||

| νopt = 16 … 36 mm²/s | range of optimum operating viscosity and efficiency | |||

| Short-term operation | νmin = 7 … 10 mm²/s | NBR2) | ϑ ≤ +78 °C | t ≤ 3 min, p ≤ 0.3 • pnom measured at port T |

| FKM | ϑ ≤ +103 °C |

| 1) | If the specified temperatures cannot be maintained due to extreme operating parameters, please contact us. |

| 2) | Special version, please contact us. |

| 3) | Equates e.g. with the VG 46 a temperature range of +5 °C to +85 °C (see selection diagram) |

Note

To reduce high temperature of the hydraulic fluid in the axial piston unit we recommend the use of a flushing and boost pressure valve (see chapter Extended functions and versions).

Explanatory note regarding the selection of hydraulic fluid

The hydraulic fluid should be selected such that the operating viscosity in the operating temperature range is within the optimum range (vopt see selection diagram).

Selection diagram

Filtration of the hydraulic fluid

Finer filtration improves the cleanliness level of the hydraulic fluid, which increases the service life of the axial piston unit.

A cleanliness level of at least 20/18/15 is to be maintained according to ISO 4406.

At a hydraulic fluid viscosity of less than 10 mm²/s (e.g. due to high temperatures in short-term operation) at the drain port, a cleanliness level of at least 19/17/14 according to ISO 4406 is required.

For example, the viscosity is 10 mm²/s at:

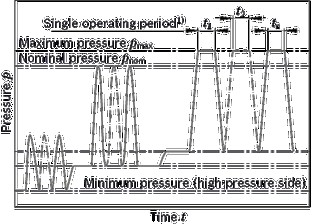

Operating pressure range

| Pressure at working port A or B (high-pressure side) | Definition | ||

| Nominal pressure | pnom | see table of values | The nominal pressure corresponds to the maximum design pressure. |

| Maximum pressure | pmax | see table of values | The maximum pressure corresponds to the maximum operating pressure within the single operating period. The sum of the single operating periods must not exceed the total operating period. |

| Single operating period | 10 s | ||

| Total operating period | 300 h | ||

| Minimum pressure | pHP min | 25 bar | Minimum pressure on high-pressure side (port A or B) required to prevent damage to the axial piston unit. |

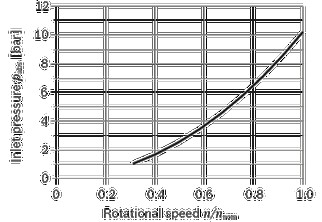

| Minimum pressure at inlet (pump operating mode) | pE min | see diagram | To prevent damage to the axial piston motor in pump mode (change of high-pressure side with unchanged direction of rotation, e.g. when braking),a minimum pressure must be guaranteed at the working port (inlet). The minimum pressure depends on the rotational speed and displacement of the axial piston unit. |

| Total pressure | pSu | 700 bar | The summation pressure is the sum of the pressures at both work ports (A and B). |

| Rate of pressure change | Definition | ||

| with integrated pressure relief valve | RA max | 9000 bar/s | Maximum permissible rate of pressure build-up and reduction during a pressure change over the entire pressure range. |

| without pressure relief valve | RA max | 16000 bar/s | |

| Case pressure at port T | Definition | ||

| Continuous differential pressure | ΔpT cont | 2 bar | Maximum averaged differential pressure at the shaft seal (case to ambient) |

| Pressure peaks | pT peak | 10 bar | t |

Note

Minimum pressure at inlet (pump operating mode)

This diagram is only valid for the optimum viscosity range of vopt = 16 to 36 mm2/s

Please contact us if these conditions cannot be satisfied.

Pressure definition

Note

Other Product Code:

| Material number | Designation |

| R902000340 | AXIAL-PISTON MOTOR A2FE125/61W-VAL181-K |

| R902000420 | AXIAL-PISTON MOTOR A2FE125/61W-NZL190 |

| R902000422 | AXIAL-PISTON MOTOR A2FE125/61W-NZL192 |

| R902004291 | AXIAL-PISTON MOTOR A2FE125/61W-VAL100-S |

| R902006756 | AXIAL-PISTON MOTOR A2FE125/61W-XAL100-S |

| R902011751 | AXIAL-PISTON MOTOR A2FE125/61W-NZL181-K |

| R902016565 | AXIAL-PISTON MOTOR A2FE125/61W-NZL191 |

| R902024673 | AXIAL-PISTON MOTOR A2FE125/61W-VZL190J |

| R902024675 | AXIAL-PISTON MOTOR A2FE125/61W-VZL192J-K |

| R902027177 | AXIAL-PISTON MOTOR A2FE125/61W-VZL191J-K |

| R902027386 | AXIAL-PISTON MOTOR A2FE125/61W-VAL181-K |

| R902031815 | AXIAL-PISTON MOTOR A2FE125/61W-VZL170 |

| R902031817 | AXIAL-PISTON MOTOR A2FE125/61W-VZL171-K |

| R902035270 | AXIAL-PISTON MOTOR A2FE125/61W-VAL106 |

| R902038722 | AXIAL-PISTON MOTOR A2FE125/61W-VZL171-K |

| R902047059 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181-K |

| R902047347 | AXIAL-PISTON MOTOR A2FE125/61W-VZL171-K |

| R902054684 | AXIAL-PISTON MOTOR A2FE125/61W-VZL180-S |

| R902054686 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181-SK |

| R902057157 | AXIAL-PISTON MOTOR A2FE125/61W-VZL171-K |

| R902060214 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181-SK |

| R902060292 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181-K |

| R902060454 | AXIAL-PISTON MOTOR A2FE125/61W-VZL180-S |

| R902060456 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181-SK |

| R902060499 | AXIAL-PISTON MOTOR A2FE125/61W-VZL171-K |

| R902063962 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181-K |

| R902068744 | AXIAL-PISTON MOTOR A2FE125/61W-VZL171-K |

| R902070993 | AXIAL-PISTON MOTOR A2FE125/61W-VAL170 |

| R902070995 | AXIAL-PISTON MOTOR A2FE125/61W-VAL171-K |

| R902073764 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181-K |

| R902075008 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181-K |

| R902077143 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181-K |

| R902078921 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181-K |

| R902080775 | AXIAL-PISTON MOTOR A2FE125/61W-VAL100-S |

| R902082452 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181-SK |

| R902084150 | AXIAL-PISTON MOTOR A2FE125/61W-VAL181-K |

| R902084279 | AXIAL-PISTON MOTOR A2FE125/61W-VZL192J-SK |

| R902084416 | AXIAL-PISTON MOTOR A2FE125/61W-VAL171-S |

| R902084428 | AXIAL-PISTON MOTOR A2FE125/61W-VAL027-S |

| R902088882 | AXIAL-PISTON MOTOR A2FE125/61W-VZL020 |

| R902088965 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181-K |

| R902094804 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181-K |

| R902096696 | AXIAL-PISTON MOTOR A2FE125/61W-VAL191J-K |

| R902099190 | AXIAL-PISTON MOTOR A2FE125/61W-VAL100F |

| R902099192 | AXIAL-PISTON MOTOR A2FE125/61W-VAL100F-K |

| R902100898 | AXIAL-PISTON MOTOR A2FE125/61W-VZL192J-SK |

| R902101622 | AXIAL-PISTON MOTOR A2FE125/61W-VZL180F |

| R902101624 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181F-K |

| R902101939 | AXIAL-PISTON MOTOR A2FE125/61W-VAL027 |

| R902102550 | AXIAL-PISTON MOTOR A2FE125/61W-VBL100-S |

| R902102594 | AXIAL-PISTON MOTOR A2FE125/61W-VZL027F-S |

| R902102595 | AXIAL-PISTON MOTOR A2FE125/61W-VZL027F-SK |

| R902117968 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181-K |

| R902117998 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181-K |

| R902121840 | AXIAL-PISTON MOTOR A2FE125/61W-VAL010-S |

| R902126584 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181-K |

| R902130528 | AXIAL-PISTON MOTOR A2FE125/61W-VZL100F |

| R902130560 | AXIAL-PISTON MOTOR A2FE125/61W-VZL027F-SK |

| R902130563 | AXIAL-PISTON MOTOR A2FE125/61W-VZL100F-K |

| R902137505 | AXIAL-PISTON MOTOR A2FE125/61W-VAL100-S |

| R902137594 | AXIAL-PISTON MOTOR A2FE125/61W-VAL100F |

| R902137596 | AXIAL-PISTON MOTOR A2FE125/61W-VAL027-S |

| R902137627 | AXIAL-PISTON MOTOR A2FE125/61W-VAL100 |

| R902137664 | AXIAL-PISTON MOTOR A2FE125/61W-VAL100 |

| R902137700 | AXIAL-PISTON MOTOR A2FE125/61W-VAL100 |

| R902137708 | AXIAL-PISTON MOTOR A2FE125/61W-VAL191 |

| R902137842 | AXIAL-PISTON MOTOR A2FE125/61W-VAL100 |

| R902137844 | AXIAL-PISTON MOTOR A2FE125/61W-VZL100-S |

| R902137846 | AXIAL-PISTON MOTOR A2FE125/61W-VAL100 |

| R902137847 | AXIAL-PISTON MOTOR A2FE125/61W-VAL100 |

| R902137873 | AXIAL-PISTON MOTOR A2FE125/61W-VZL100-S |

| R902137874 | AXIAL-PISTON MOTOR A2FE125/61W-VZL100-S |

| R902137875 | AXIAL-PISTON MOTOR A2FE125/61W-VZL100-S |

| R902137876 | AXIAL-PISTON MOTOR A2FE125/61W-VZL100-S |

| R902137877 | AXIAL-PISTON MOTOR A2FE125/61W-VZL100-S |

| R902137878 | AXIAL-PISTON MOTOR A2FE125/61W-VZL100-S |

| R902137880 | AXIAL-PISTON MOTOR A2FE125/61W-VZL100-S |

| R902137895 | AXIAL-PISTON MOTOR A2FE125/61W-VZL100-S |

| R902138009 | AXIAL-PISTON MOTOR A2FE125/61W-VZL100-S |

| R902138015 | AXIAL-PISTON MOTOR A2FE125/61W-VZL027-S |

| R902138016 | AXIAL-PISTON MOTOR A2FE125/61W-VZL027-S |

| R902138018 | AXIAL-PISTON MOTOR A2FE125/61W-VZL027-S |

| R902138078 | AXIAL-PISTON MOTOR A2FE125/61W-VBL100-S |

| R902138104 | AXIAL-PISTON MOTOR A2FE125/61W-VAL027-S |

| R902138121 | AXIAL-PISTON MOTOR A2FE125/61W-VAL100F-S |

| R902138174 | AXIAL-PISTON MOTOR A2FE125/61W-VAL010-S |

| R902138487 | AXIAL-PISTON MOTOR A2FE125/61W-VZL100-S |

| R902149042 | AXIAL-PISTON MOTOR A2FE125/61W-XAL100-S |

| R902150209 | AXIAL-PISTON MOTOR A2FE125/61W-VZL188-S |

| R902150273 | AXIAL-PISTON MOTOR A2FE125/61W-VZL188-S |

| R902150290 | AXIAL-PISTON MOTOR A2FE125/61W-VZL178-S |

| R902155053 | AXIAL-PISTON MOTOR A2FE125/61W-PZL100-S |

| R902155555 | AXIAL-PISTON MOTOR A2FE125/61W-VAL106F |

| R902155594 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181-S |

| R902155621 | AXIAL-PISTON MOTOR A2FE125/61W-VZL181F-S |

| R902155710 | AXIAL-PISTON MOTOR A2FE125/61W-VZL192J |

| R902155726 | AXIAL-PISTON MOTOR A2FE125/61W-VZL171-S |

| R902155745 | AXIAL-PISTON MOTOR A2FE125/61W-VZL192J-S |

| R902155771 | AXIAL-PISTON MOTOR A2FE125/61W-VZL100F-S |

| R902155781 | AXIAL-PISTON MOTOR A2FE125/61W-VZL192J-S |

Leader Industrial Manufacture Co.,Limited. is a professional agent of foreign brand plunger pumps and hydraulic pumps. It mainly deals in Resroth,Yuken,Daikin,Nachi,Vickers,Sumitomo,Tokimec,Uhida,Yeoshe,Dension, and other European and American brands of original oil pumps, pump cores and accessories. Leader Industrial is committed to providing professional suppliers of hydraulic machinery equipment and accessories.It is widely used in injection moulding machine, die-casting machine, oil press, ship machinery, construction machinery, concrete pump truck, mixing truck, construction machinery, rotary drilling machine, bulldozer, loader, roller, paver, crane machinery, forklift, coal mine machinery, port machinery, oil field machinery and other heavy engineering machinery series.

Direction of flow

| Direction of rotation, viewed on drive shaft | |

| clockwise | counter-clockwise |

| A to B | B to A |

R902137736 A2FM107/61W-VZB010 Rexroth Axial Piston Pump/motor

R902137736 A2FM107/61W-VZB010 Rexroth Axial Piston Pump/motor

10MCY14-1B high pressure hydraulic axial piston PumpR909441351 A7VO80LRH1/61R-PZB01-S Rexroth A7VO Series Axial Piston Pump

10MCY14-1B high pressure hydraulic axial piston PumpR909441351 A7VO80LRH1/61R-PZB01-S Rexroth A7VO Series Axial Piston Pump

PVD-3B-56L 3D-5-221 OA Nachi PVD Series Flow Variable Piston Pump

PVD-3B-56L 3D-5-221 OA Nachi PVD Series Flow Variable Piston Pump

J-V23A3RX-30 Daikin variable piston pump V series

J-V23A3RX-30 Daikin variable piston pump V series

© 2017 - 2025 Beijing Voyage Machinery Parts Co., Ltd. All Rights Reserved